Our machines

Machine suited for each of your applications.

-

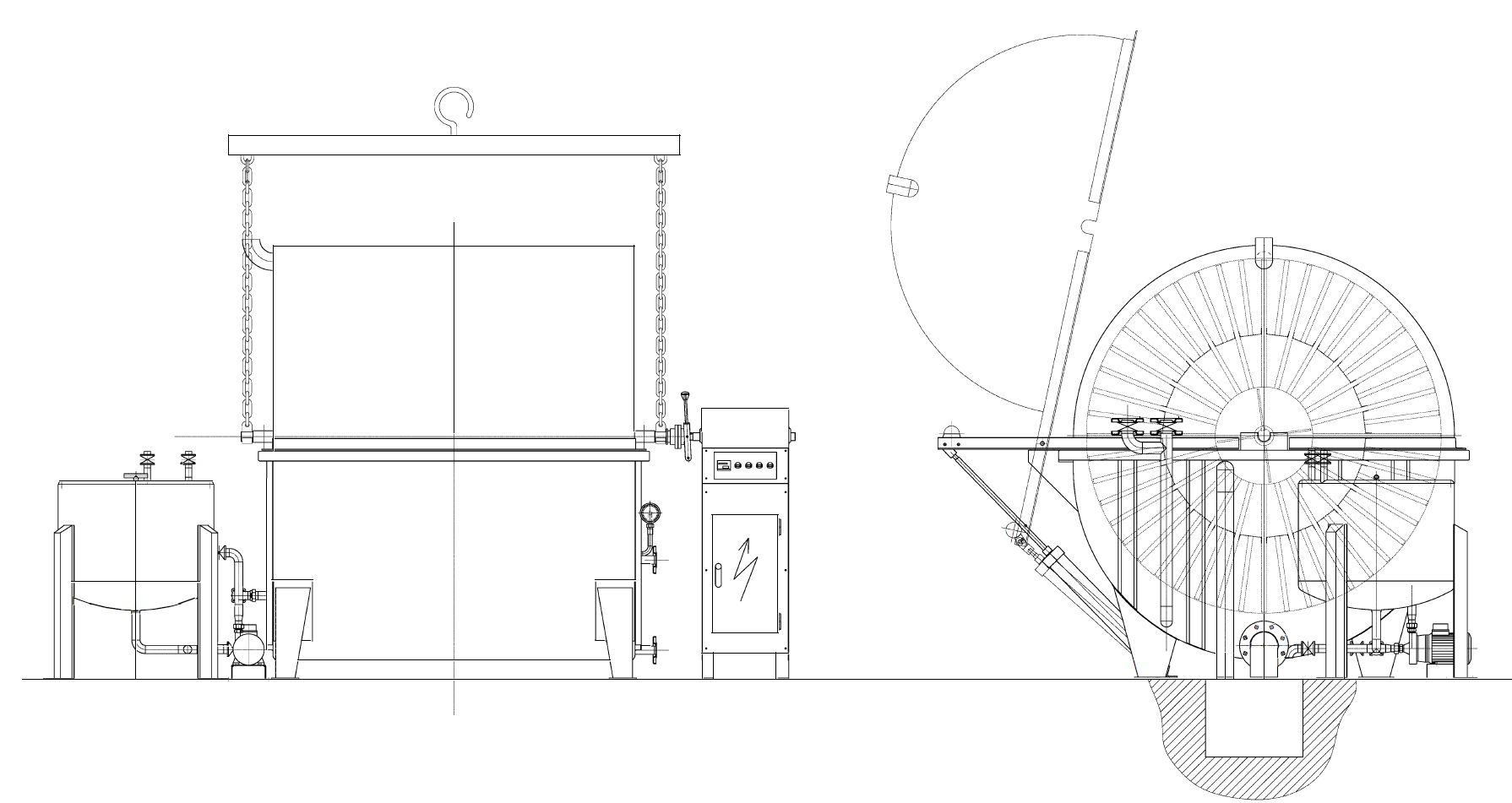

The first dyeing machine dedicated to natural dyeing

Customer benefits :

- Versatility 4 in 1 : piece dyeing, hank dyeing, garment dyeing and drum for extraction of tinctorial infusion

- Productivity : elaboration of protocoles (30% time saving) and small productions (50% time saving)

- Space requirement close to that of a washing machine

- Automated and connected (recording of protocols, automatic mordanting/dyeing cycles)

- Internal draining : the bath can be refilled several times for a liquor ratio of 1:1 (against 40 in a winch !)

-

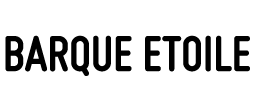

The ultra flexible, high temperature piece dyeing machine, for laboratory, prototyping and capsule collection production

Customer benefits :

- Versatility of the machine : from light-weight fabrics such as muslin to heavy fabrics such as knitted Trevira

- 3'' and 4'' interchangeable jets

- Teflon rods basket to limit mechanical friction

- Teflon guide ring to facilitate fabric flow

- Eco-efficient machine with low liquor ratio

- EURO-5 pump for high flow variability and low water height

- Single-arm reel = only one mechanical seal.

-

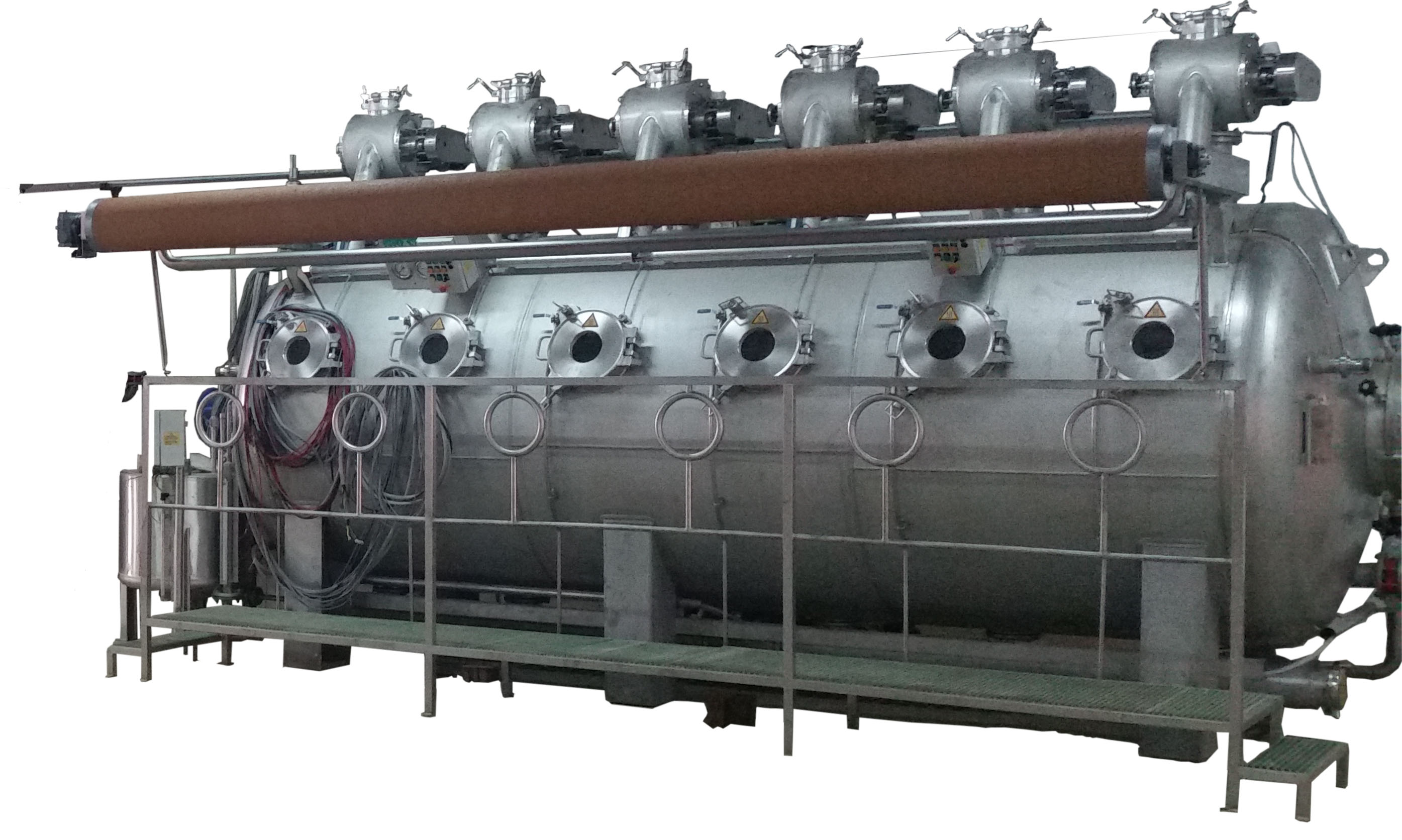

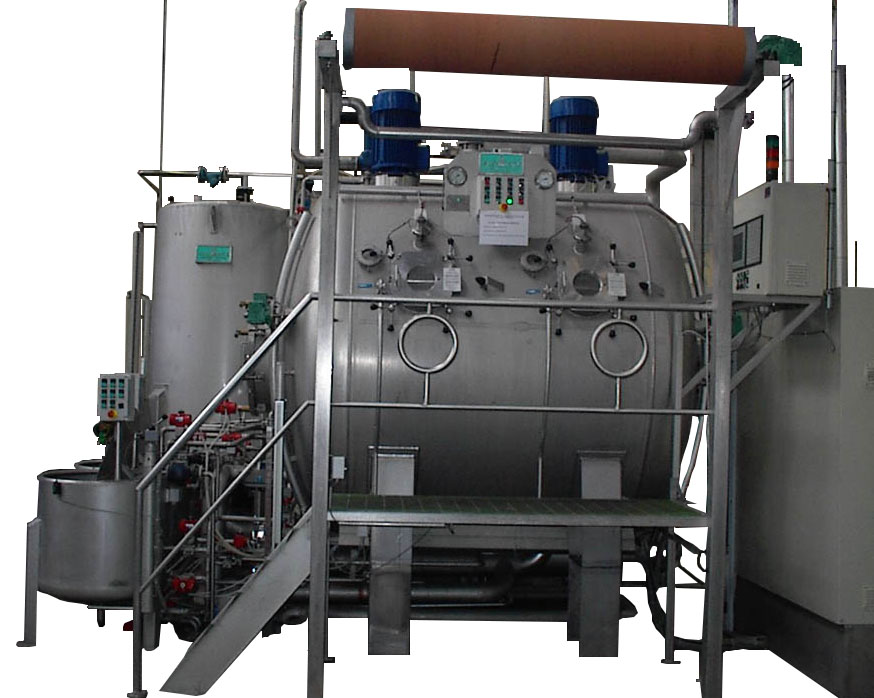

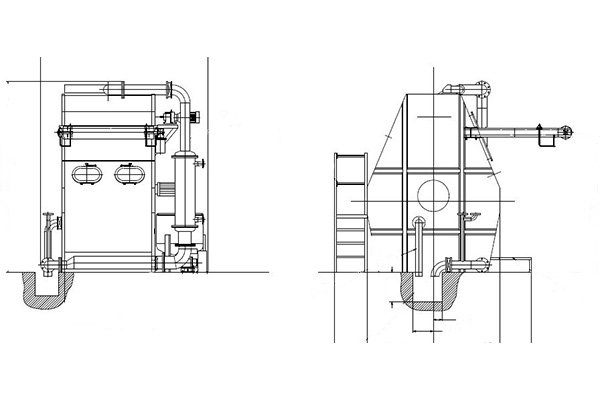

The dyeing machine with exceptional profitability and environmental friendliness.

Customer benefits :

- The only dyeing machine that can have a return on investment lower than 1 year for certain applications

- Rotating beam machine with constant 1:3 liquor ratio regardless of loading weight

- DyeSpection sampling door

- Continuous control and monitoring of the pump flow rate in closed-loop operation

- Gradual increase of DP (pressure) at each start

-

The dyeing machine with air blower for a perfect unison without rolling.

Customer benefits :

- Inflated and unfolded fabrics by air action

- Multiple exposures of the material in contact with the bath, different exposure with each rotation

- Air promotes the dyeing of crease sensitive fabrics such as Viscose or Lycra

- The air blown is captured inside the machine to guarantee the continuity of the dyeing process

- Uniform dyeing from one end of the selvedge to the other, open knitwear treated without stitching, no rolling up

- Controlled folding of multidirectional fabric for optimal storage and capacity

-

The multi-purpose and ultra-customizable dyeing machine.

Customer benefits :

- More than 20 possible jet models suitable for a very complete range of fabrics and for the most demanding dyes.

- Machine of self-cleaning design.

- Removable rear basket.

- Exclusive pump turbine, the fruit of 50 years of experience.

- Minimized compaction problems.

- Adjustable deflector allowing control of fabric storage for ideal loading of each tube.

- Lobbed tube for improved tissue circulation.

- Detwisting system.

-

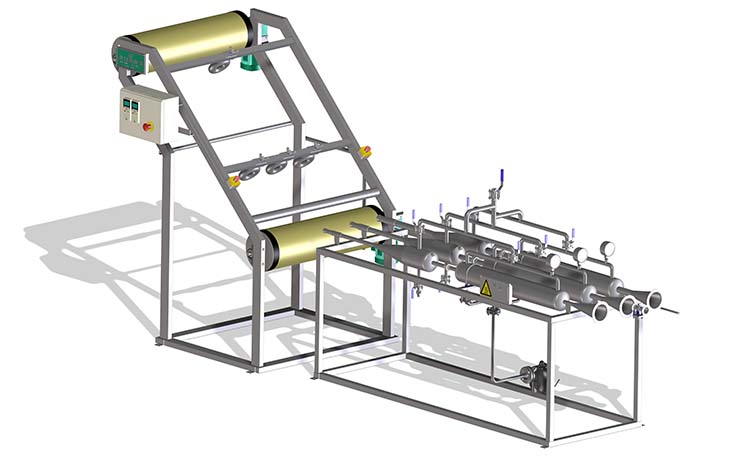

The prototyping or small production machine.

Customer benefits :

- Allows the confirmation of a process

- Allows excellent reproducibility on industrial batches

- Can be delivered with an electric heat exchanger and thus be integrated in a space not connected to the fluid networks (for machines with a capacity of 1-10 kg)

-

The dyeing machine for the most fragile fabrics

Customer benefits :

- Crease marks are prevented by lowering the spinner

- Dyeing by river

- Able to handle widths of 4 to 5 meters

- Available in low or high temperature

- Fast, 2-step door opening for safety

-

The high-temperature laboratory jet dyeing machine.

Customer benefits :

- High temperature sampling machine (140°C)

- Chemicals are introduced directly through the loading door

- Easy integration in a laboratory: water, electricity and compressed air are all that is needed

-

The finishing machine providing an exceptional and long-lasting feel.

Customer benefits :

- Exceptional touch thanks to the air drive system, the result of 50 years of experience

- Creation of smooth and silky touch and feel

- Possibility of wet and dry treatments with a tumbler effect

- Intensive removal of excess pigment in the air nozzle

- Optimized storage of the fabric in a PTFE rod basket

- Filter with air-circuit stuffing filter

- Air humidity control

-

The rope dyeing machine without spinner.

Bénéfices clients :

- No crushing of the fabric (no spinner)

- Machine without spinner

- Air drive only

- Exceptional touch AND dyeing in one machine

- Low-noise machine: fan inside the machine

- Guaranteed process homogeneity: air captured inside the machine

- Anti-blocking fabric system

- High Temperature or Low Temperature

-

The dyeing machine with or without air blower for a perfect unison without rolling.

Customer benefits with air :

All the advantages of the RIVIERA EG at atmospheric temperature.

Customer benefits without air :

Inflated terrycloth type fabrics.

-

The dyeing machine offering an exceptional touch.

-

The atmospheric or high temperature dyeing machine.

-

The sock putting machine to obtain crash, pleated, tie & dye effects in dyeing.

-

The old-fashioned dyeing machine.

-

Exclusive refurbishing service for your machines

Customer benefits :

- Your machines refurbished and equipped with the latest technology (less water, less energy)

- Unavailability of only a few weeks

- Machines that evolve and adapt to your new qualities

- A lower cost (30 to 50%) compared to the price of a new machine

- Machines that can be used for another 20 years